Job Overview

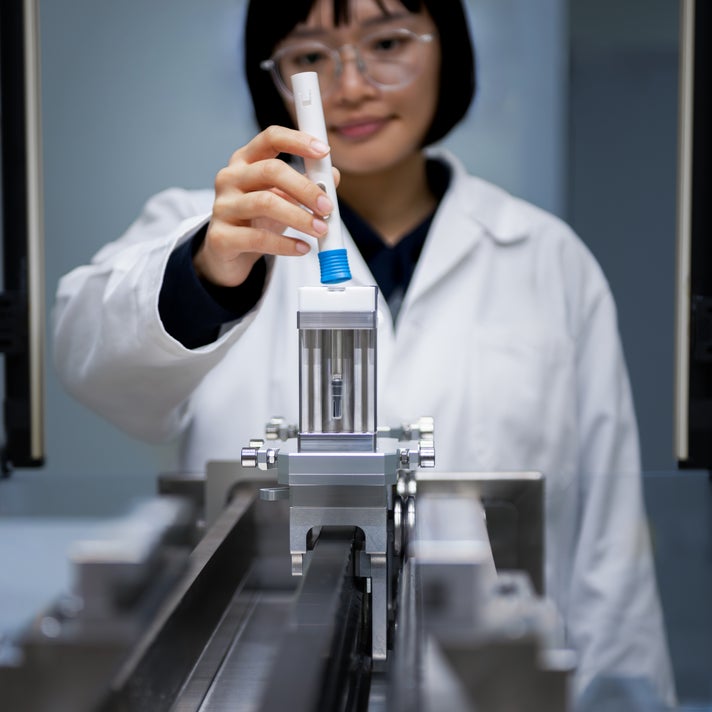

As a Tooling & Maintenance Technician at SHL Medical's Charleston facility, you'll be integral to our injection molding operations, focusing on the meticulous assembly, disassembly, and maintenance of plastic injection molds. Your role ensures the seamless production of advanced drug delivery systems by upholding equipment reliability and process efficiency. Working alongside a dedicated team, you'll engage in hands-on technical tasks and preventative maintenance, contributing directly to the quality and innovation of our healthcare solutions. This position offers a unique opportunity for professional growth in a high-tech manufacturing environment.

Main Responsibilities

- Support the assembly and disassembly of plastic injection molds including hot runners.

- Lead daily predictive and preventative maintenance including documentation

- Support machine and tool set ups.

- Lead execution of maintenance schedule to achieve production goals

- Maintain controlled areas and environmental monitoring in injection molding production

- Actively participate in mold/production event response

- Lead review and author SOP’s and other documents, as required

- Ensure all event response and production operations activities are correctly documented in SAP

- Maintain spare part stock management and record stock levels in SAP

- Participate in Systematic Problem-Solving tools to establish Root Cause Analysis & resolve equipment issues

- Partner with Process Owners on practical changes or improvements to equipment & department work practices

- Record/review production data and activities per SHL work instructions

- Follow all safety and environmental requirements in the performance of duties

- Lead implementation of mold and auxiliary system/equipment reliability improvement projects

- Other accountabilities, as assigned

Required Qualification

- High school diploma or equivalent required (AAS degree in related field preferred, or equivalent military training or industrial training or an equivalent combination of education experience

- 5+ years of relevant work experience

- Knowledge/experience in the following areas: crane operation, compressed air/pneumatic actuators and systems, electro-mechanical controls, robotics, optical sensor systems, resin drying, molds, fluid thermal control systems, hot runners and injection molding machines

- 1+ years proven track record in mold maintenance or injection molding industry

- Demonstrated ability to support & actively participate in event response activities in highly automated / 24/7 production settings

- Able to document problems & works to bring them rapidly to solution

Desired Qualification

- Ability and experience with automated records systems such as SPC, MES, EWM, SAP

- Proficiency in reading schematics, wiring diagrams & other technical documents.

- Experience in planning/organizing work, managing execution, checking results & revising the work plan in accordance with the daily work plan

- Computer literacy

We Offer

- Competitive compensation package

- Modern working environment with state-of-the-art facilities and technologies

- Challenging assignments in a fast-growing and innovative industry

- Position in a dynamic, international team of highly skilled professionals

- Various opportunities for personal and professional development within a global organization

How we hire

We like to keep things simple and efficient.

Once you’ve applied, it may take up to three weeks to review your application and get the first call with a recruiter.

Our recruitment process is focused on allowing you to show your personality, experience and competencies while giving you a great sense of who we are.

Grounded in belonging, we strive for excellence

With almost 6,000 employees of 77+ different nationalities, we take pride in the inclusive and collaborative environment we have built - one where a true sense of belonging fosters meaningful exchange and shared growth. Together, we invest in our future to maintain our leadership position in drug delivery systems.