Company Overview

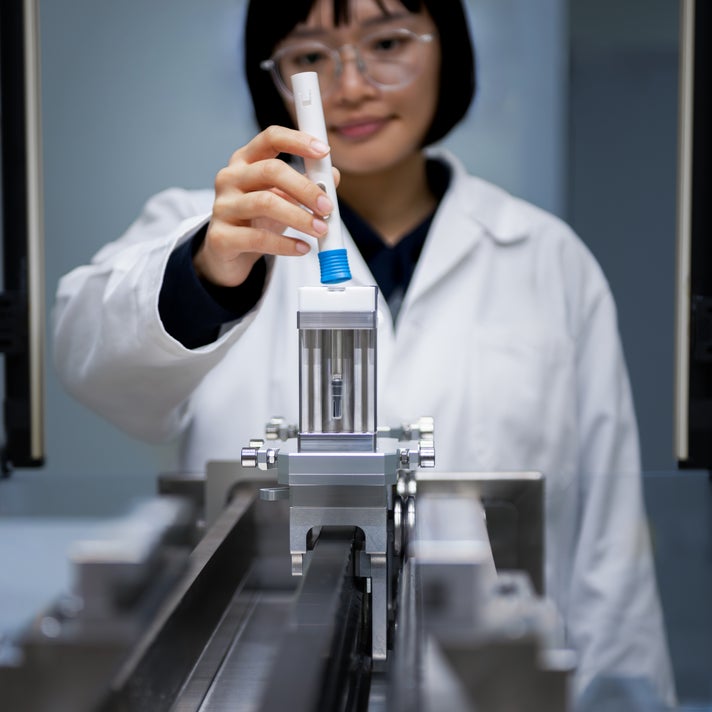

SHL Advantec is a global provider of high-performance, turnkey manufacturing and packaging solutions for medical devices, healthcare products, and other applications in the automotive, aerospace, and construction industries. We offer fully integrated precision tooling and advanced automation services that give our customers access to streamlined solutions for improved efficiency and lower development risks. From clinical pilots to full-scale manufacturing, our dedicated group of over 600 tooling and automation experts across the globe offers the right-sized solutions for any production requirements.

Advantec Technology located in Taiwan offers a full range of automated solutions to support any scale of pre-clinical, clinical, or commercial supply. Ranging from manual, semi-automated, to fully automatic assembly and testing machines, our solutions address every stage of the product lifecycle. With dedicated team of automation experts, we work on the entire lifecycle of all our equipment solutions – from design, engineering, CNC machining, to final equipment manufacturing and assembly. We have built more than 1,500 machines delivered to over 15 countries.

Job Overview

Production Planning and Control Role alignes materials, labor, and machinery, production planning which ensure that everything runs as what it should be. Production planning and control connect the dots between what needs to be made and when it’s produced thru demand management, schedule planning, and control framework. In a world where agility matters more than ever, strategy, efficiency, responsiveness, and control are the key.

Acting as a pivot coordinator, the role should work closely with project team, production line, and material control for a robust arrangement. Align schedule of production and procurement as per material demands which achieve the JIT material supply to Advantec Technology projects and order.

Main Responsibilities

- Demand Management and Planning

- Keep the demand log

- Scan and clarify the spare part demand from customers

- Issue material request/production order.

- Communicate with PM and SCM team on the matters of project material demand schedule, production plan, and progress.

- Create accurate and timely material plans and schedules according to the BOM structure and assembly sequence to support on time material supply

- Update the estimated supply schedule

- Visualize material shortage and supply status in timely manner

- Escalate effectively the material abnormal status

- Facilitate expedite or needful actions to mitigate supply risk.

- On time supply and delivery

- Assist Supply Chain Management to establish a rolling capacity requirements and supply plan for the forecast.

- Support project management to achieve organizational goal by with mature ability to perform/prioritize/allocate job tasks independently.

- Responsible for following all applicable SOPs and WIs at all the times.

- Responsible to follow the principle of GMP.

- Work cross-functionally with other departments based on improvement needs in order to provide better service to the whole group.

- Carry out other duties as assigned.

- Require independent judgment. And learn/ develop advanced technology proactively.

Required Skills & Qualifications

- Bachelor’s Degree Diploma. Three plus years' experience in production scheduling and/or material planning position.

- SAP or ERP experience for 1+ year

- Knowledge of basic MRP principles.

- Ability to focus in an environment of conflicting demands with a cool and efficient demeanor. In depth knowledge of production and inventory control (P&IC) techniques.

- Understanding of manufacturing processes preferably in an assembly environment. Must have the ability to read and understand structural drawings and BOM.

- Requires high energy, good attitude, and a strong sense of urgency.

- Ability to perform calculations such as percentages, ratio and data governance.

- Basic computer skills with the ability to adapt to a variety of software applications.

- Ability to communicate with others to exchange information both orally and in writing.

- Project management experience

- Experience in ISO9001

- Low to medium volume mechanical manufacturing environment.

How we hire

We like to keep things simple and efficient.

Once you’ve applied, it may take up to three weeks to review your application and get the first call with a recruiter.

Our recruitment process is focused on allowing you to show your personality, experience and competencies while giving you a great sense of who we are.

Grounded in belonging, we strive for excellence

With almost 6,000 employees of 77+ different nationalities, we take pride in the inclusive and collaborative environment we have built - one where a true sense of belonging fosters meaningful exchange and shared growth. Together, we invest in our future to maintain our leadership position in drug delivery systems.