Location: Charleston, South Carolina, US

Reporting to: Manufacturing Supervisor – Device Assembly

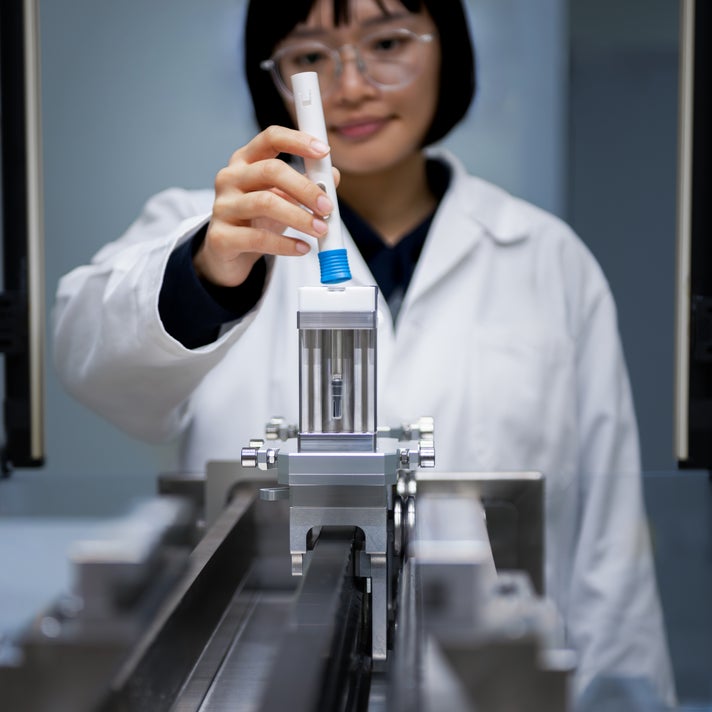

SHL Medical is the world-leading solution provider in the design, development, and manufacturing of advanced drug delivery systems with more than 5000 employees worldwide. Our customers include top pharmaceutical and biotech companies from around the globe that require innovative devices such as auto-injectors or pen injectors to effectively deliver their drugs. Headquartered in Switzerland since late 2018, with sites in Sweden, Taiwan, and the United States.

Job Overview

Lead Production Technicians (LPTs) will be a key team member in supporting the startup and continued success of the Device Assembly Operations at a newly constructed state-of-the-art facility located in North Charleston SC. The LPTs will be the resident mechanical experts who have full responsibility, on their assigned shift, for the fully automated assembly line for which they are responsible. In addition to being the first line of defense in addressing downtime and waste issues, the LPTs will also be the primary point of contact for line performance. The LPTs will also have oversight of the Production Technicians assigned to their line to ensure optimal performance, minimal waste, and an efficient operation. This position offers an exciting opportunity for growth and development, including the chance to undergo training at our facility in Taiwan

Main Responsibilities

- Oversight of technical operators in Medical Device Assembly Operations

- Demonstrate a Safety-First mindset, proactively enforce all Safety Policies and Procedures

- Pro-actively ensure all shift personnel are operating in accordance with all pre-established Quality Policies and Procedures

- Analyze machine performance using data as well as mechanical knowledge to pro-actively address machine issues

- Be the primary point of contact for all Safety, Quality, and Production based metrics relevant to your line of responsibility

- Communicate all line performance issues to the on-shift supervisor and escalate to next level support when needed

- Appropriately manage your line of responsibility to ensure the maximum OEE is achieved each shift

- Perform weekly, monthly, semi-annual, and annual PMs as required to ensure that your line of responsibility remains reliable and in optimal condition

- Pro-actively engage with and continuously coach Production Technicians on your line of responsibility to enable them to be an extension of yourself with regards to mechanical aptitude and line management skills

- Pro-actively make suggestions for Safety, Quality, and Production improvements

- Provide oversight to new hire training with the understanding that you are responsible for the final training approval from a mechanical and line management standpoint

- Be willing to utilize your skills and knowledge to pro-actively assist other production lines or departments in the plant

- Ensure operations and practices comply with established procedures and records

- Ensure in-process tests and inspections are performed in accordance with standard procedures

- Analyze and solve complex operational issues to minimize impact to overall performance of the operation

- Constantly improve technical knowledge of the assembly equipment for which you are responsible

- Support evaluation, specification, installation, and validation of new manufacturing equipment as needed

- Serve as project member or project leader on improvement programs as needed

- Willing to voluntarily take on additional task and responsibilities, as needed, to ensure the continued success of our operation as well as the company at large.

- Perform all job duties and responsibilities in a compliant and ethical manner and in accordance with all applicable healthcare laws, regulations, and industry codes

- Perform other task and/or duties as assigned

Skills and Qualification

- Minimum 2-3 years of operating complex automated manufacturing equipment

- Demonstrated ability to progress through an organization to advanced technical roles

- Prior experience within a start-up facility (Preferred)

- Extensive technical knowledge of highly automated manufacturing equipment

- Technical knowledge of Servos, Cams, Pneumatics, Motors, Gears, Pumps, etc…

- Conceptual knowledge of vision systems, sensors, drives, etc…

- Proven ability to troubleshoot mechanical systems to correctly identify root causes

- Ability and Desire to be the informal on the floor leader of your production line

- Prior experience in highly regulated industry (Highly Preferred)

- Knowledge of SAP and MES systems preferred

- Above average communication skills and the ability to work as part of highly productive teams

- Ability and Desire to challenge status quo and willingness to never stop improving

- Demonstrated Results Driven mentality who understands that wins and losses happen as a TEAM

We Offer

- Competitive compensation package

- Modern working environment with state-of-the-art facilities and technologies

- Challenging assignments in a fast growing and innovative industry

- Position in a dynamic, international team of highly skilled professionals

- Various opportunities for personal and professional development within a global organization

How we hire

We like to keep things simple and efficient.

Once you’ve applied, it may take up to three weeks to review your application and get the first call with a recruiter.

Our recruitment process is focused on allowing you to show your personality, experience and competencies while giving you a great sense of who we are.

Grounded in belonging, we strive for excellence

With almost 6,000 employees of 77+ different nationalities, we take pride in the inclusive and collaborative environment we have built - one where a true sense of belonging fosters meaningful exchange and shared growth. Together, we invest in our future to maintain our leadership position in drug delivery systems.