About SHL Medical

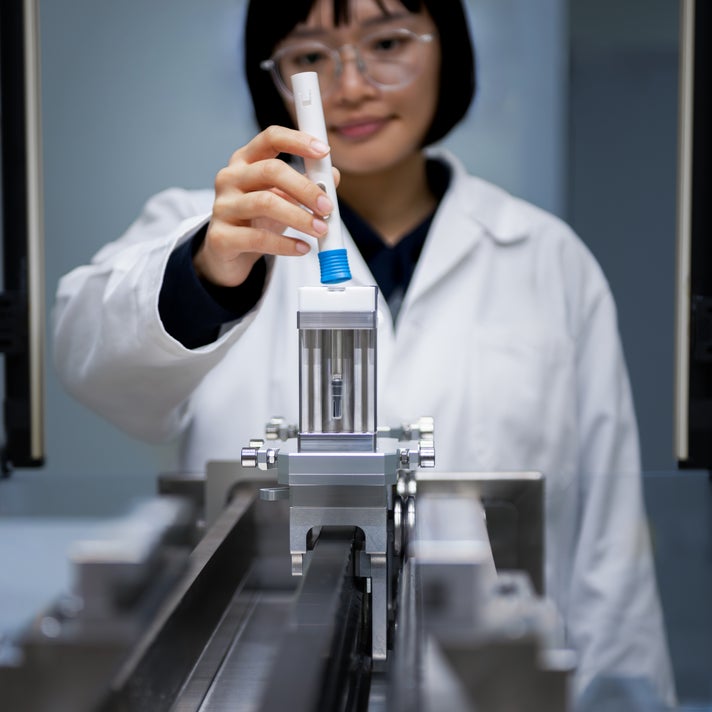

SHL Medical is a world-leading provider in the design, development, and manufacturing of advanced self-injection devices. With a global team of 6,000 employees, we partner with leading pharmaceutical and biotech companies to deliver innovative autoinjectors, pen injectors, and other drug delivery systems that ensure effective treatment for patients. Headquartered in Switzerland since 2018, with key operations in Sweden, Taiwan, and the US, we are united by a commitment to innovation, impact, and growth. Together, we empower our people to develop solutions that make a meaningful difference in the lives of millions of patients while fostering a supportive, inclusive, and dynamic workplace for our colleagues.

Job Overview

The Plastic Component Engineer (Molding Process Development) is responsible for establishing and developing injection molding processes for new injection molding tools, ensuring repeatability and robustness from development through series production. This role provides key technical input on DFM, tooling, equipment, and process validation, collecting scientific evidence to ensure molding processes meet customer specifications.

Main Responsibilities

- Lead moulding process development activities for assigned projects and tool sets, following established business processes.

- Collaborate closely with Operations Engineering, Tooling, Metrology, Project Engineering, and other key stakeholders throughout all development phases.

- Drive enhancements in manufacturability, process robustness, and overall cost efficiency.

- Define TURS (Tooling User Requirements Specifications) and verify compliance during the design review process.

- Establish clear acceptance criteria for molds and plastic components to ensure conformance to specifications.

- Lead and support trial-shot activities, including documentation review, issue clarification, and approval workflows.

- Conduct or support root cause analysis for mold or component deviations.

- Determine necessary tool steel adjustments based on development findings and test results.

- Support engineering sample builds and provide troubleshooting assistance for manufacturing-related issues.

- Coordinate cross-functional stakeholders and maintain clear, structured technical communication.

- Lead additional process or productivity improvement initiatives aligned with business needs, focusing on efficiency, quality, and cost optimization.

Required Skills & Qualifications

- Bachelor's degree or above in Mechanical, Manufacturing, or Polymer Engineering.

- Minimum 5+ years’ experience in Engineering related , with at least 3 years focused on injection moulding in a regulated industry (medical device preferred).

- Strong understanding of molding processes, tooling, polymers, and optimization.

- Skilled in scientific molding, DoE, statistics, CAD, DFM/FMEA.

- Excellent communication and team work skills.

- Familiar with in-mold pressure sensors and multi-cavity tool development.

- Familiar with quality system requirements is beneficial (ISO 13485, ISO 14971, FDA 21 CFR 820, GMP

- RJG Master Molder certification will be an advantage.

What We Offer

-

Challenging assignments in a fast-growing and innovative industry.

-

A multicultural team and modern working environment with state-of-the-art facilities and technologies.

-

A place where we take pride in the inclusive and collaborative environment we have built - one where a true sense of belonging fosters meaningful exchange and shared growth.

-

Various opportunities for personal and professional development within a global organization.

-

Flexible hours and hybrid working policy.

How we hire

We like to keep things simple and efficient.

Once you’ve applied, it may take up to three weeks to review your application and get the first call with a recruiter.

Our recruitment process is focused on allowing you to show your personality, experience and competencies while giving you a great sense of who we are.

Grounded in belonging, we strive for excellence

With almost 6,000 employees of 77+ different nationalities, we take pride in the inclusive and collaborative environment we have built - one where a true sense of belonging fosters meaningful exchange and shared growth. Together, we invest in our future to maintain our leadership position in drug delivery systems.